Quality Policy

At PAN Electronics, we are committed to providing our customers with high-quality products and services that meet or exceed their expectations. We adhere to the guidelines and requirements set forth by ISO 9001:2015, and we continuously strive to improve our quality management system to ensure that our products and services are of the highest quality.

We at PAN Electronics convey our strict adherence to quality policies including that

- We will consistently meet or exceed our customers' expectations by providing them with products and services that are reliable, safe, and meet all applicable standards and regulations.

- We will continuously improve our quality management system through ongoing training, evaluation, and feedback from our customers and employees.

- We will ensure that all employees are fully trained and understand their roles and responsibilities in achieving our quality objectives.

- We will maintain an open and transparent communication with our customers, suppliers, and stakeholders, and we will take their feedback into account to continuously improve our products and services.

- We will regularly review and update our quality management system to ensure that it is effective, efficient, and meets the needs of our customers and our business.

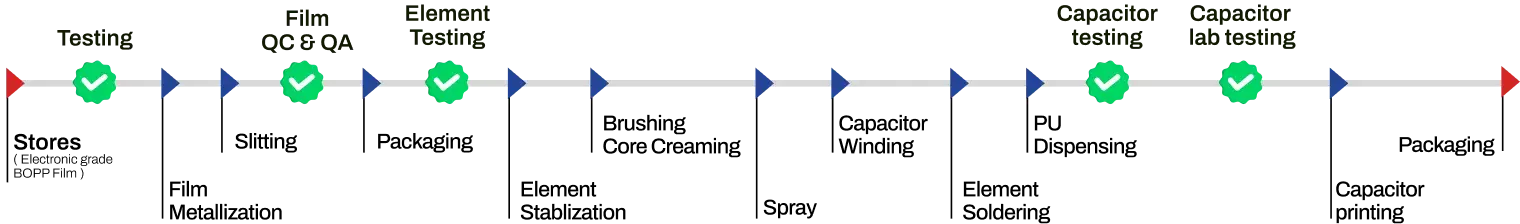

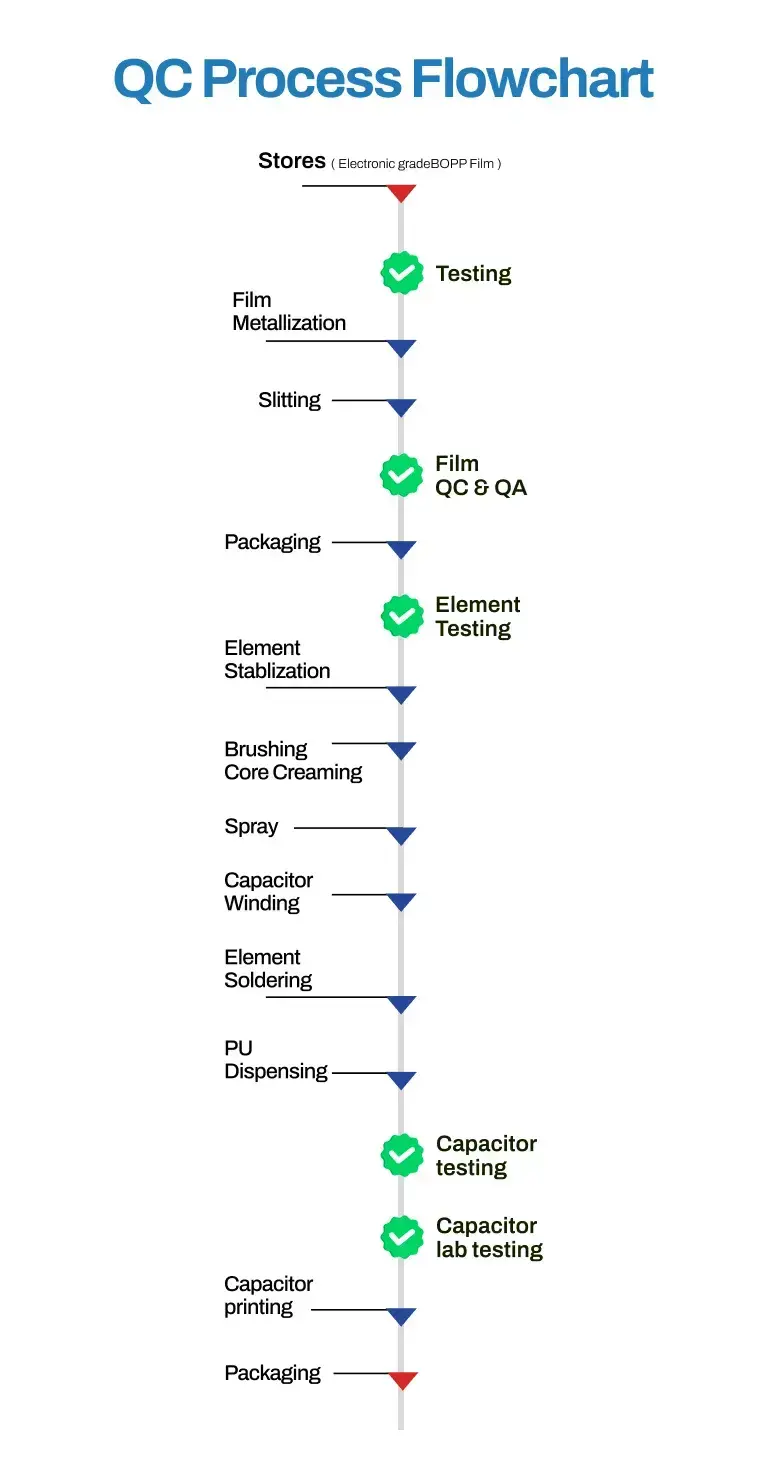

QC Process Flowchart

Inspection & Testing

Procedures at PAN Electronics

Inspection & Testing for Metallised Film

- BOPP thickness variation by digital micrometer

- Corona Treatment Test

- Visual Inspection to check for damages wrinkles / winding / damages.

- Inspection during Metalizing stage for parameters like Resistivity, Type, Free Margin

- Adhesion Test during post Metalisation using sample inspection

- Quality inspection during packing stage & vacuum sealing

- Inspection during slitting stage for Reel Width, Free Margin Width, and online resistivity test & Surface finish of slitted reel

- Post Slitting Resistivity test by Nagy meter and resistivity meter

- BDV test by BDV meter

- Visual Inspection for scratches and wrinkles

- Shelf-life test

- Pin hole testing

Inspection & Testing for Capacitors

- Capacitance by Capacitance meter / LCR meter

- High voltage test between terminals by HVDC meter

- High voltage between terminals by HVAC meter

- Measurement of tangent of loss angle by LCR METER

- Charge discharge type test

- Endurance type test

- Damp heat test

- Discharge Device test

- Self-healing test

- High voltage test between terminals and container by HVDC & HVAC meter

- Insulation Resistance between terminals and container by IR meter

- Destruction type test

- Impulse type test

- Efficacy type test

- capacitance test by rated voltage

- Tangent loss test by rated voltage

SA8000: 2014

The SA8000 Standard and Certification System provide a framework for organizations of all types, in any industry, and in any country to conduct business in a way that is fair and decent for workers and to demonstrate their adherence to the highest social standards.

REACH

REACH is a regulation by the European Union intended to improve the protection of human health and the environment. It stands for Registration, Evaluation, Authorization and Restriction of Chemicals. PAN Electronics has made the necessary preparations to ensure compliance with the regulation.

ISO Certification

We are ISO certificated for Quality Management (ISO 9001:2015), Environmental Management (ISO 14001:2015), and Occupational Management (ISO 45001:2018), reflecting our unwavering commitment to excellence in every aspect of our operations.

CE Certificate

CE marking is a certification mark that indicates conformity with the essential legislative health, safety, and environmental protection requirements defined by the so-called Product Directives for products sold within the European Economic Area (EEA). The CE marking certifies PAN Electronics declaration that our product meets the requirements of the applicable EC directives.